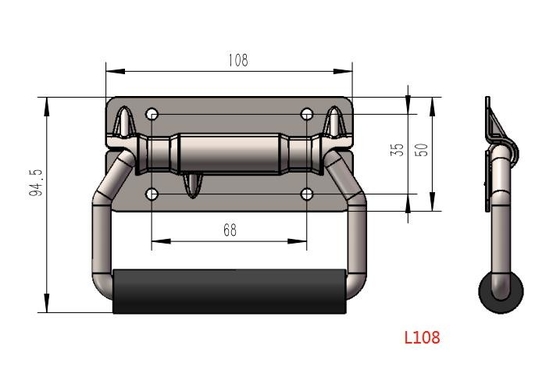

L108 Rubber Grips Spring Loaded Folding Pull Stainless Steel Chest Handles

Product Description

L108 Chest handles with munting plate, you can attach these handles directly to the various doors and drawers on the box toolboxes, machines and equipment you need. When not in use, their grips fold away.Round grips allow your hand to pivot in any direction.

Spring in these handles keeps the folding grip flush with the mounting plate and prevents rattling.

Product Parameters

| Product name |

Rubber Grips Spring Loaded Folding Pull Stainless Steel Chest Handles |

| Material |

Stainless steel / Steel |

| Surface treatment |

polish / zinc plated |

| NO. |

L108 |

| Usage |

For toolbox, machinery, flight case, |

| Storage |

Keep in cool and dry place away from corrosive liquid |

| Discount |

The quantity is larger,the unit price is lower |

| Port |

Qingdao |

Product drawings

What is the surface treatment of handle?

1. Electroplating is a widely used surface treatment method for iron handles. Electroplating on the surface of the handle can well isolate the air layer and make the handle's service life significantly longer.

2. The stainless steel handle is not subjected to electroplating. The surface treatment of the stainless steel handle is generally shock light, polishing, wire drawing and so on.

About Laizhou Huiding Hardware Co., Ltd

Laizhou Huiding Hardware Co.,ltd. is a collection development,production,sales as one of the production enterprise,specializing in the production of toggle latches, handles, toggle clamps, machinery hardware and other industrial hardware, with a variety of equipment over 60 sets,and passed the ISO 9001 international quality management system certification.

Our products are widely used in automobiles, ships, high-speed trains, aerospace, medical equipment, nuclear power plants and other engineering projects, in the Belt and Road Initiative, Olympic stadium construction, green energy development and other aspects have made outstanding contributions. Our clients comes from all over the country, exported to Middle East,Southeast Asia,Europe,North America, Russia and other countries and regions.

Quality Control

1. The quality inspection of raw materials includes indicators such as steel plate hardness;

2. Regular data detection of products, such as length, width, height and weight;

3. Product bearing capacity test;

4. Salt spray test to test the corrosion resistance of products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!